Solar Power World 's editorial team had the great opportunity to speak to 27,000 friends at this year's RE+ show in Anaheim, California. In addition to happy hour and a lunch stop from a food truck, we spent time visiting as many booths as possible to check out the new products on offer.

The solar and storage industry has come a long way since the last major trade show of 2019. Solar panels are bigger, tracks are more flexible, and inverters are smarter. In recent years, many impressive developments have taken place to facilitate the deployment and storage of solar energy. We've done our best to pick some of our favorites for 2022.

Be sure to visit our online database for a more comprehensive list of the best products of 2022.

Truly modular designs make energy storage devices more durable and easier to install

This can be seen on the Canadian Solar Cube EP

SPW editors have only picked a drum kit once in the past five years to compile our picks. Since batteries are used in energy storage systems, especially in the residential market, most of them are just gray boxes with nothing interesting inside. Typically, Tesla increased available power from 13.5kWh of electricity, but a 5kW inverter often left most households with two or more units to meet their electricity needs. Tesla's nickel-manganese-cobalt (NMC) works great, but many safety-conscious installers and homeowners want more brands of lithium iron phosphate (LFP) that can be easily installed outdoors.

SPW editors have only picked a drum kit once in the past five years to compile our picks. Since batteries are used in energy storage systems, especially in the residential market, most of them are just gray boxes with nothing interesting inside. Typically, Tesla increased available power from 13.5kWh of electricity, but a 5kW inverter often left most households with two or more units to meet their electricity needs. Tesla's nickel-manganese-cobalt (NMC) works great, but many safety-conscious installers and homeowners want more brands of lithium iron phosphate (LFP) that can be easily installed outdoors.

Enter Canadian Solar's truly customizable and modular EP Cube energy storage system. A single, easily expandable unit has a 7.6kW inverter on top, a stackable battery in the middle and all cables to the bottom panel. Each battery uses an average of about 3.3 kWh, while some require just over 13.5 kWh, but not as much as 27 kWh. The LFP-based system can be floor or wall mounted, and the entire unit is rated to NEMA 4X, the highest outdoor rating we've seen for any ESS system.

Each of the EP Cube's 3.3 kilowatt-hour battery modules weighs about 70 pounds, making it much easier to install than a 250-pound Powerwall system. This means fewer hands are required for the installer to connect and operate the battery. It's still a gray box, but the EP Cube's metallic sheen makes this ESS attractive enough to display outside the home.

Solar permitting and design programs help installers expand into new areas

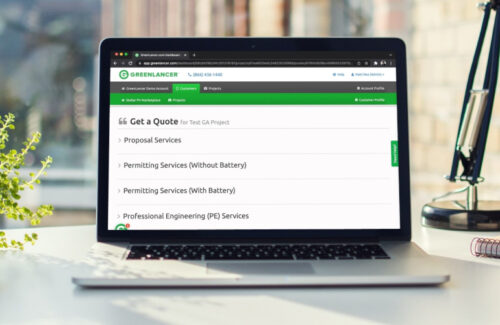

The GreenLancer permit can be found on the Design and Engineering Marketplace

A constant obstacle for solar installers looking to expand into new geographic areas is the varying permitting and design requirements of local building departments. Learning the details and provisions of each class can take time and resources, with inevitable delays if there are errors in document permissions.

A constant obstacle for solar installers looking to expand into new geographic areas is the varying permitting and design requirements of local building departments. Learning the details and provisions of each class can take time and resources, with inevitable delays if there are errors in document permissions.

Solar software vendors are constantly looking to reduce these costs, which hurt solar installers large and small. The provider has created a marketplace that connects solar companies with design and engineering firms across the country that already have expertise in the nuances of local construction services.

"Having design experience in all of these areas basically helps an installer start out without a general understanding of that aspect," says Matt Rea, GreenLancer's vice president of revenue operations.

GreenLancer is a platform that allows installers to pay design and engineering firms for network permits, bond applications and other documents at rates standardized by software providers. GreenLancer's in-house support team supports the entire process, acting as an intermediary between the contractor and the project company and resolving any issues that arise during the process.

Some contractors use GreenLancer as a complete design and engineering. Others use it as a redundancy. they have an in-house design team but need help during busy seasons.

“Because of the ebb and flow of the solar industry, sometimes we have to tap ourselves on the shoulder and say, "Hey, we need to send you projects." We are excited to fill that gap,” Rio said.

Looking to the future, GreenLancer also plans to expand into field services, not only connecting installers with project companies, but also connecting project owners with installers if they want to add batteries to an existing project or need help with operation and maintenance.

"It's really a vision. the installer can come to us and do this design and engineering work, but they can also see how our installation works,” says Rhee.

In this increasingly digital age, online marketplaces like GreenLancer help installers fill design, engineering and development gaps without adding new departments.

The innovation takes the single-axis solar probe into new territory

Found on Nevados Engineering off-road tracks

One of the biggest obstacles to deploying single-axis solar probes is mountainous terrain. Hiring a civil engineering service to level the ground and create a flat work area can add significantly to the cost of a solar project. However, this was necessary to allow the solar controller's drive mechanisms to rotate rows of panels that previously could not compensate for soil erosion. Now that is changing.

One of the biggest obstacles to deploying single-axis solar probes is mountainous terrain. Hiring a civil engineering service to level the ground and create a flat work area can add significantly to the cost of a solar project. However, this was necessary to allow the solar controller's drive mechanisms to rotate rows of panels that previously could not compensate for soil erosion. Now that is changing.

Nevados Engineering is one of the leading manufacturers of single-axis solar trackers for this environment. The company's All Terrain Tracker (ATT) software has an internal slope tolerance of 37% overall and can handle slope changes of up to 26% per base. The key feature that makes this possible is a pivot bearing mounted on top of each base, which allows each panel gap to be set at different angles while maintaining rotation of the panel row.

The Nevados solution reduces the cost of aligning large-scale solar installations and opens up unidirectional tracking in mountainous regions previously limited by fixed sloped racks. In addition to resisting tilts, the ATT has been environmentally tested in long-distance tests and is designed to operate in winds of up to 80 mph, but stall at 45 mph. Its controls are wireless and self-propelled. The ATT can safely handle snow loads of up to 50 square feet, and the system comes with an extended 10-year structural warranty and a five-year warranty on the actuators and controls.

With new products like the ATT, single-axis solar tracks can adapt to new terrain and increase structural strength.

The steel frame and bracket make the solar panels more durable and environmentally friendly

Spotted on Ryzen Energy's Titan and the first Solar Series 7

The first 7-series solar panel with a steel rear drive

Aluminum works well with the solar industry. Its light weight and corrosion resistance make it the preferred material choice for mounting solar panel frames and accessories. But at a time when people are paying close attention to the carbon footprint of all components, stronger frame and support options are catching on.

Steel is the main material from which some doors are made. Risen Energy has offered a steel frame option for its Titan crystalline silicon solar panels, and First Solar plans to use steel back rails in its new Series 7 thin-film modules. Both companies cited a smaller carbon footprint as one of the main ones. Reasons to switch to aluminum. . According to Risen Energy, the production of one ton of aluminum emits 11.2 tons of CO2 , compared to just 1.8 tons of carbon dioxide per ton of steel. And switching to steel has very little effect on the final product. the steel-framed Titan weighs just three pounds more than the aluminum-framed model.

Solar cells that use steel instead of aluminum gain additional energy benefits, which is beneficial for solar cells coming to market on a large scale. First Solar's Series 7 module is taller and has a larger surface area than the Series 6 modules, so the steel rear support rails provide more structural support for the series' frameless solar panels. 7. First Solar is leveraging the local steel industry for lower carbon emissions and will dedicate all of its new plants in the U.S. to Series 7 units with no aluminum parts.

As the cost of the solar part of the panel decreases, the frames and brackets become the largest cost of the finished solar module. On the global market, aluminum is on average 2.6 times more expensive than cold-rolled steel, so removing this expensive element would make solar panels cheaper and more environmentally friendly.

Inverters offer entry-level backup options for solar consumers

SMA appears in the American Sunny Boy Smart inverter

Energy storage is becoming more affordable thanks to state and federal incentives, but it's still not economically feasible for all homeowners. New inverters give solar homeowners only some of the benefits of backup power with the ability to easily add batteries later.

Energy storage is becoming more affordable thanks to state and federal incentives, but it's still not economically feasible for all homeowners. New inverters give solar homeowners only some of the benefits of backup power with the ability to easily add batteries later.

Since 2015, SMA America has integrated the Safe Power Supply feature into its Sunny Boy transformers. These transformers include terminals for two connectors to connect to a four-way or two-way electrical outlet under the unit or through the home's main primary load. . In the event of a power outage during the day, homeowners can connect their critical load, such as a refrigerator, to this backup solar outlet and store it at up to 2 kW until the grid is repaired.

Now the company is changing the name and adding new system options to the updated Sunny Boy Smart Energy inverter, which is expected to launch in mid-2023. This basic version of Solar Backup is called Backup Secure, but the company now offers. two more powerful backup options. . The first is Backup Select, which requires the installation of an optional SMA accessory, but can double the power without batteries to about 4 kilowatts of backup power when exposed to sunlight. Backup Select switches feature a dedicated electrical panel with six pre-wired switches so that if the power goes out during the day, these circuits will automatically reconnect.

The most advanced iteration of the Sunny Boy inverter is the SMA Backup Home, a complete battery backup solution for extra power day and night. This system can be connected to the home's main electrical panel to provide multiple circuits.

All SMA scalable solutions are based on the leading Sunny Boy inverter, so there is flexibility as homeowner needs, energy costs and incentives change over time.

“For cheap entry, they can have daily automatic backup with clean energy, and if the utility starts pushing them to add storage in a year or two, they can easily add a battery on the same platform without making any changes. ...” Rob Lamendola, Product Manager, Home Solutions, SMA Americas.

The future of solar is getting easier as hybrid inverters with built-in backup options become the norm.

A complex system of pulleys turns the ladder into a sun pulley

The metric unit is visible in the elevator

Solar cell efficiency continues to increase, but with this generational leap so does size and weight. Manufacturers of complementary technologies must adapt to these new dimensions and results. First of all, the fastenings must be done more carefully to keep the panels of this format in place. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. . n.. n.. n.. n. But those who greatly feel the heavy panels are the installers, the installers; special contractors work on the roof.

Solar cell efficiency continues to increase, but with this generational leap so does size and weight. Manufacturers of complementary technologies must adapt to these new dimensions and results. First of all, the fastenings must be done more carefully to keep the panels of this format in place. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. . n.. n.. n.. n. But those who greatly feel the heavy panels are the installers, the installers; special contractors work on the roof.

Solar shader analysis and other arrays are known for creating test arrays and now have a pool system that brings the miirukkut. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. connected.. .. .. .. .. .. .. . .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. attached... . .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. The elevator module is made of fiberglass for residential solar installation. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. ... n.. n.. n.. n.. n. At the top of the panel there is a crane and a patent hook for the solar panel. .. .. The operator pulls the rope and lifts the panel up the stair ramp. .. A panel on the roof allows any backward movement. .. ..

There are safety precautions for solar installers working at height, such as equipment and roofing. It is true that God knows better. Solar panels have never been light, but now they are more than 50 pounds, and a tool like a module lifter reduces the risk of lifting materials, and module builders have more freedom in panel dimensions. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. ... n.. n.. n.. n.